Project Title:

Scientific research enabling the development of the process of using recycled photovoltaic panels in the production of metal alloys.

Project Acronym:

PV-Recyc

This research is part of the project No. 2022/45/P/ST5/02712 co-funded by the National Science Centre and the European Union Framework Programme for Research and Innovation Horizon 2020 under the Marie Skłodowska-Curie grant agreement no. 945339.

- Host Institution – AGH University of Science and Technology || Strona główna — Serwis Akademii Górniczo-Hutniczej (agh.edu.pl)

- Faculty – Faculty of Metals Engineering and Industrial Computer Science (WIMiIP)|| Wydział Inżynierii Metali i Informatyki Przemysłowej AGH

- Department – Department of Plastic Processing of Metals and Extractive Metallurgy|| Projekty – Katedra Plastycznej Przeróbki Metali i Metalurgii Ekstrakcyjnej (agh.edu.pl)

- Principal Investigator – dr inz Pradeep Padhamnath|| Pradeep Padhamnath – Katedra Plastycznej Przeróbki Metali i Metalurgii Ekstrakcyjnej (agh.edu.pl)

General Project Description

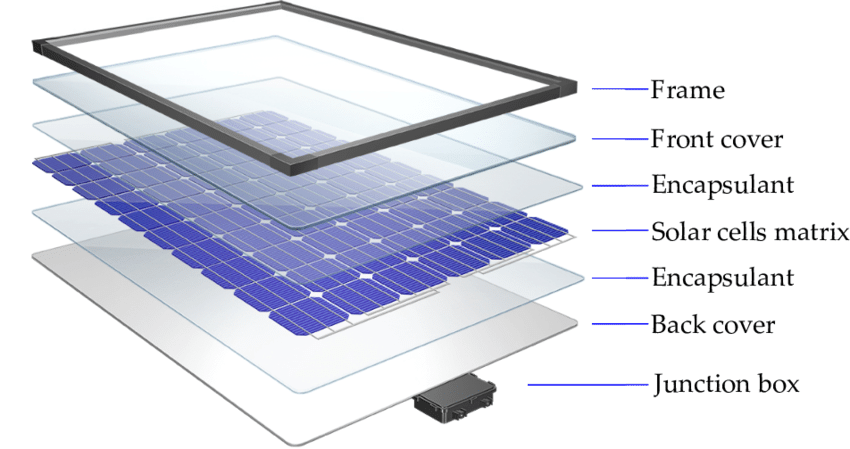

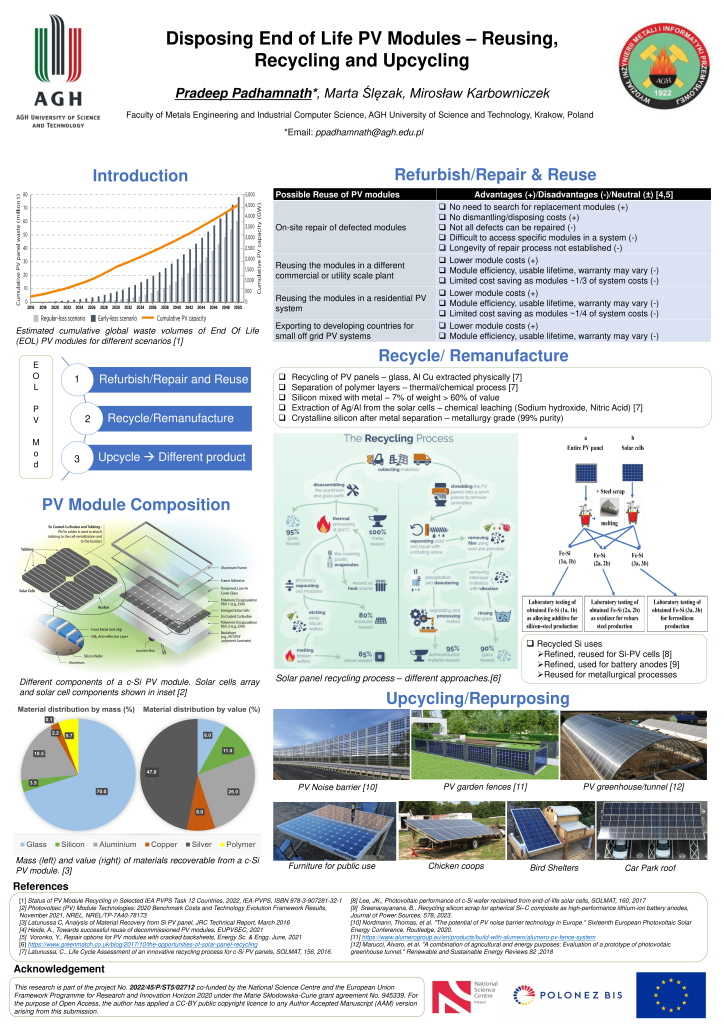

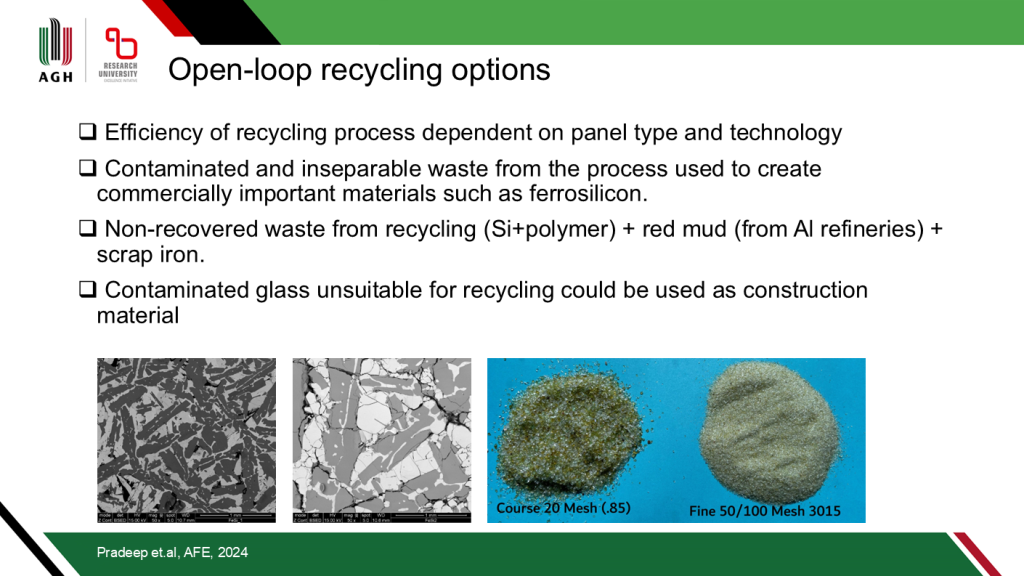

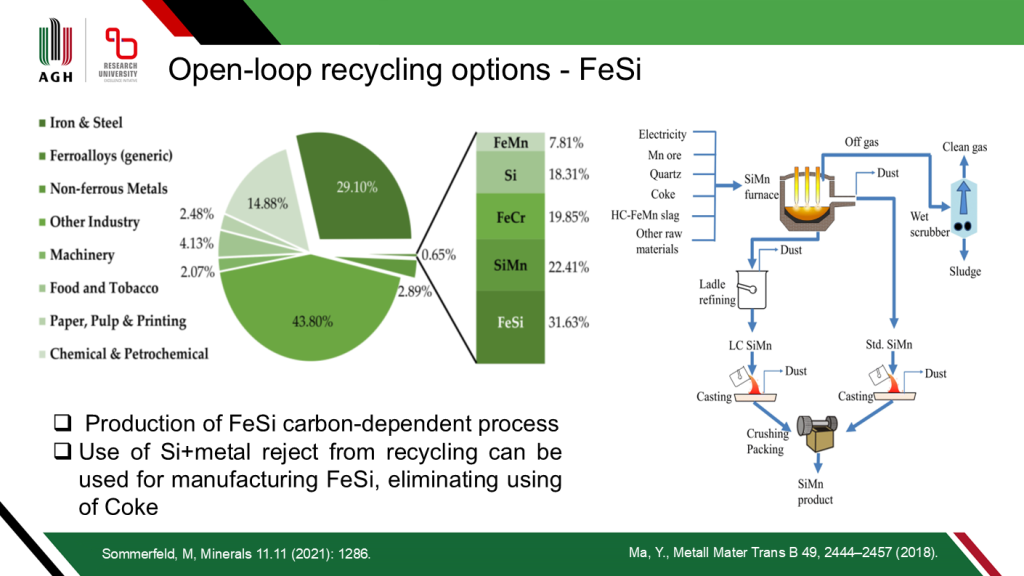

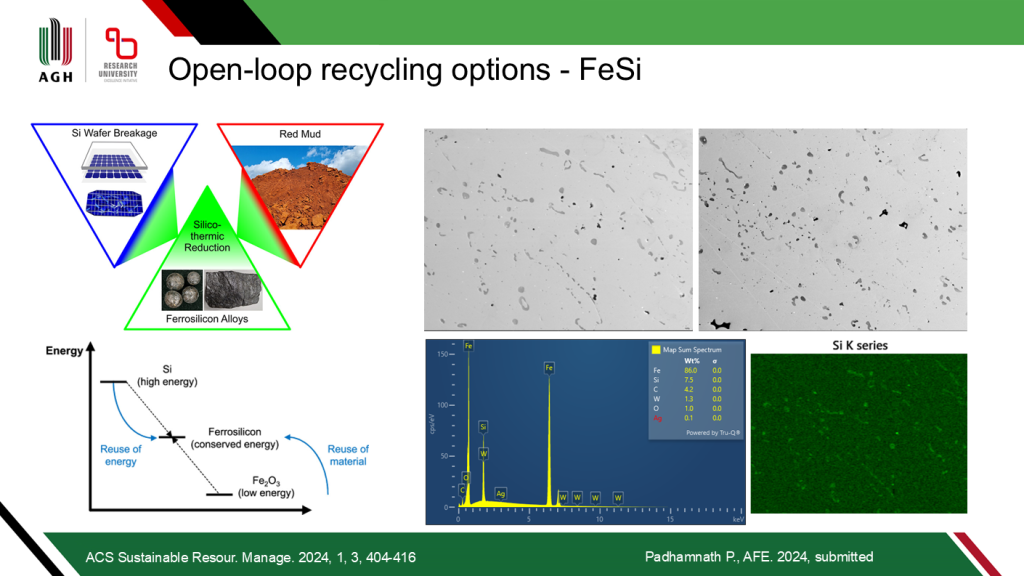

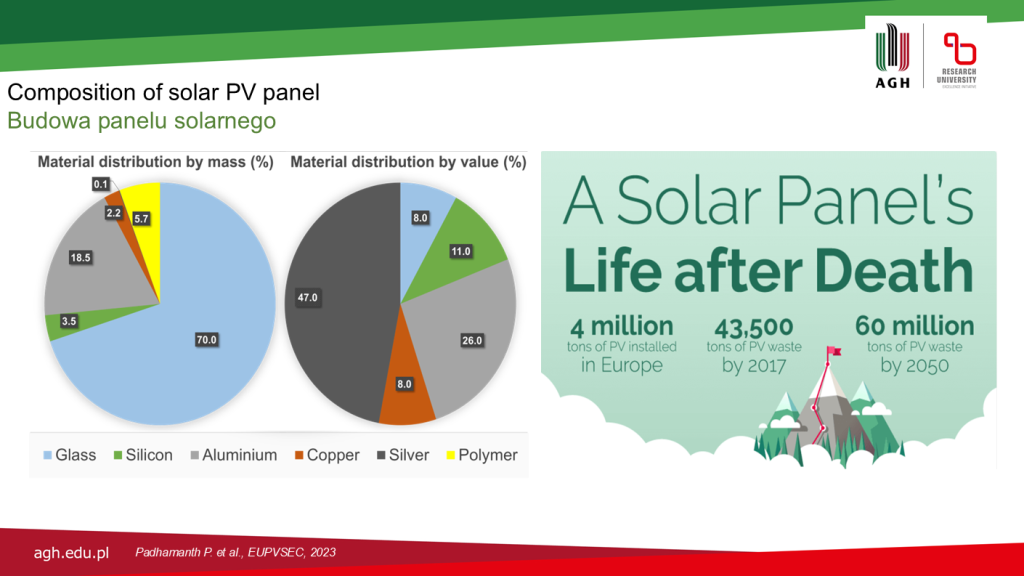

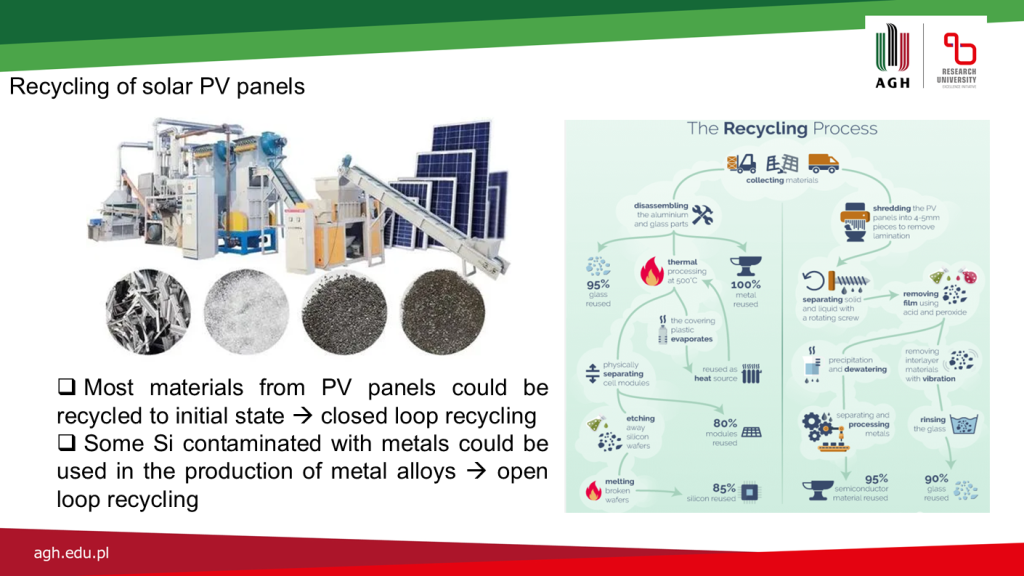

The exponential growth of the photovoltaic (PV) installations is an important and desirable element in the global response to climate change. A typical PV module has a lifetime of 20-25 years. However, some will be damaged during production, transportation, handling or installation, and some will even stop functioning after sometime, while some would be discarded during testing called as factory reject modules. Increased use of PV panels for energy production would also lead to enormous volumes of PV waste that needs to be dealt with in an environmentally responsible manner. The growing amounts of PV panel waste presents new environmental and waste management challenges. Recovery of raw materials from the PV panels, or researching other applications of recycled PV modules could lead to establishment of new solar PV end-of-life industries. In-fact, solar PV recycling would be of paramount importance for the transition into a sustainable and economically viable renewables-based energy future. The importance of developing pathways for PV module recycling has been acknowledged and some recycling processes have been developed. However, the complexity of the recycling process is one of the prime reasons hindering their large-scale implementation and consequently limiting the growth of PV module recycling industry. Almost all research activities on module recycling has been focused on c-Si PV modules due to the fact that c-Si technology commands more than 95% of the solar PV industry. Almost all recycling efforts for crystalline silicon PV modules available in literature are directed towards recovering various materials such as external wiring, glass layer and the aluminium frames from waste c-Si PV panels to be used again in c-Si PV panels manufacturing. Several chemical means could be employed to recover precious metal (usually silver) and metal free silicon from the mixture which could be recycled. While chemical treatment to obtain pure silicon appears to be promising and attractive, it has several drawbacks. The process has to be tailored for different cell types and architectures. This makes the process extremely complex and prohibitively expensive. Additionally, the chemicals required for this process are highly hazardous and dangerous. To promote the recycling of the waste c-Si PV panels, it is important to research and develop safe and simple methods of recycling. Hence, developing alternate pathways for recycling crystalline silicon PV modules that are simple and do not require complicated processes and hazardous chemicals is an essential and promising research direction. For example, ferrosilicon (FeSi) could easily be obtained from discarded c-Si PV panels by melting the panels with scrap steel and could be used as deoxidizer, or Si carrier in manufacturing other metal alloys such as steel rebars and silicon steel used in electric motors. This could be the simplest method of recycling c-Si PV panels as it involves minimum processing steps and eliminates the use of toxic and hazardous chemicals. The aim of this project is to develop simple recycling process for c-Si PV modules. Ferrosilicon made directly from PV modules, would contain some impurities such as silver, aluminium, phosphorus and boron in extremely small quantities. To understand the impact of impurities on the properties of the alloy, it will be imperative to understand the basic underlying scientific principles of a multi-component alloy system with trace impurities. Hence, the main aim of the project will be to research the impact of the typical impurities from the solar panel on the properties of Fe-Si phase system. Although the Fe-C-Si phase system has been investigated to some extent, the behavior of a multicomponent system involving minute quantities of Al, Ag, B and P is largely unknown. After understanding the behavior of the multi-component system, research would be done to further verify the findings by producing ferrosilicon alloys of various composition as governed by the kinetics and thermodynamics of the multicomponent phase system and characterizing their properties. The ferrosilicon would be produced with recycled materials obtained from PV modules and scrap steel, and hence would also include minor impurities. The ferrosilicon would be characterized and compared with the commercially available ferrosilicon using scientific methods. Further, the ferrosilicon produced from the recycled PV panels would be used for producing silicon steel, rebar steel and higher-grade ferrosilicon samples. These samples produced in the laboratory would be compared with the commercially available samples. This comparative study would help us establish and further improve the process. Thus, the project will enable the scientific community to understand the behavior and impact of the trace-impurities on the properties of the alloys produced from end of life PV panels. The knowledge could later be helpful to establish the feasibility of using materials recovered from recycled PV panels in the production of metal alloys used in day-to-day activities, while addressing the issue of recycling PV panel waste. The process, if established, is expected to recycle 100% of the PV panel waste.

Social Media Mentions

- https://www.linkedin.com/posts/solar-decathlon-india_sdihighlights-solardecathlonindia-sdi-activity-7132238484752261120-Lf8Z?utm_source=share&utm_medium=member_android

- https://www.linkedin.com/posts/srinath-nalluri-05628966_electrohydraulic-fragmentation-processing-activity-7297396195432308736-RpVI?

- https://www.linkedin.com/posts/skn-ekoenergia_renewableenergy-ekoenergia-photovoltaictechnology-activity-7260269940597792769-vKDG?

Project Team

- dr inż. Pradeep Padhamnath

- prof. dr hab. inż. Mirosław Karbowniczek

- dr inż. Marta Ślęzak (June,2023 to Nov,2023)

- dr inż Mateusz Kopyściański (From Feb,2024)

- dr inż Filip Kuśmierczyk (From May, 2024)

- mgr inż. Grzegorz Ślęzak (From June, 2023)

Students

Administrative Assistant

Publications

- Padhamnath Pradeep at al., Disposing End of Life PV Modules – Reusing, Recycling and Upcycling, in Proceedings of EUPVSEC-2023. ISBN: 3-936338-88-4, DOI: 10.4229/EUPVSEC2023/5DV.2.62

- Theoretical Investigation of the Impact of Impurities in Recycled Silicon Used for the Production of Ferrosilicon (Proceedings)

- Electrohydraulic fragmentation processing enabling separation and recovery of all components in end-of-life silicon photovoltaic panels (journal)

- Development of PV panel recycling process enabling complete recyclability of end-of-life silicon photovoltaic panels (journal)

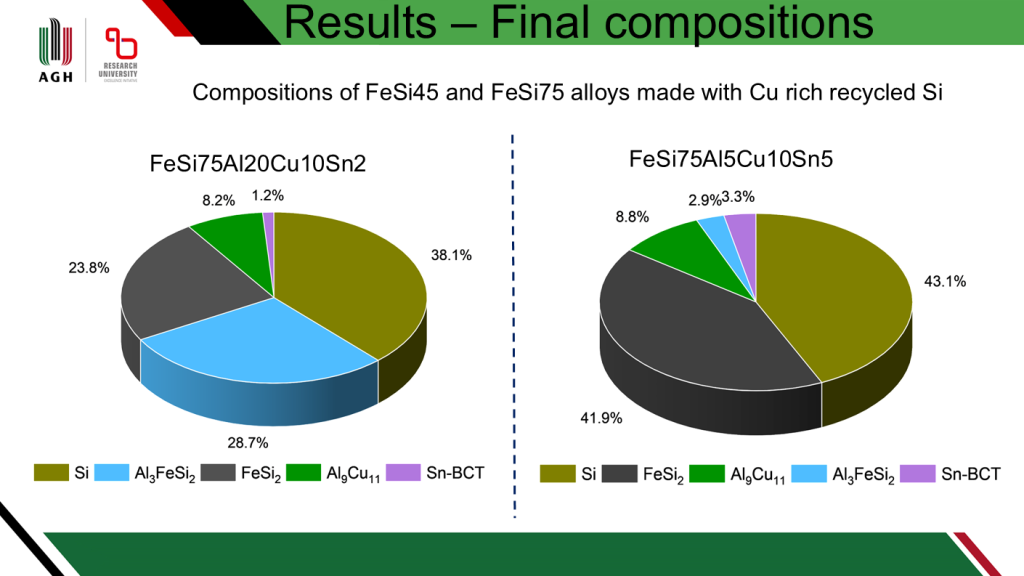

- Realization of a Novel FeSiAlCuSn Multicomponent Alloy and Characterization of Intermetallic Phases Formed at Different Temperatures During Cooling (journal)

Conferences

1. EUPVSEC, Lisbon, Portugal, 10-22 September 2023

Disposing end of Life PV Modules – Reusing, Recycling and Upcycling at EUPVSEC, Lisbon, 18-22 September 2023.

Visit us at the Europe’s largest solar PV conference in Lisbon, Portugal, from 18 – 22 September 2023, to see our research update on recycling of end-of-life PV modules. Click here to access the complete schedule of the conference.

2. SiliconPV-2024, Chambery, France, 14-17 April 2024

3. The Marie Skłodowska-Curie Actions (MSCA) conference, Mons, Belgium, 18-19 April 2024

A host of eminent speakers, all experts in their own field, shared their knowledge and experience throughout the two days. The conference achieved its goal to create a fertile ground for productive discussions between researchers, representatives from the public and private sector, policy makers and all stakeholders which, one way or another, play a role in researchers’ careers. This event offered a space where these exchanges gave birth to practical, inspiring results. In this forum, the participants received the opportunity to share their achievements, their needs, their ideas and their experiences. Together, the participants helped in shaping the future of research careers while honouring the legacy and visionary spirit of Marie Skłodowska-Curie.

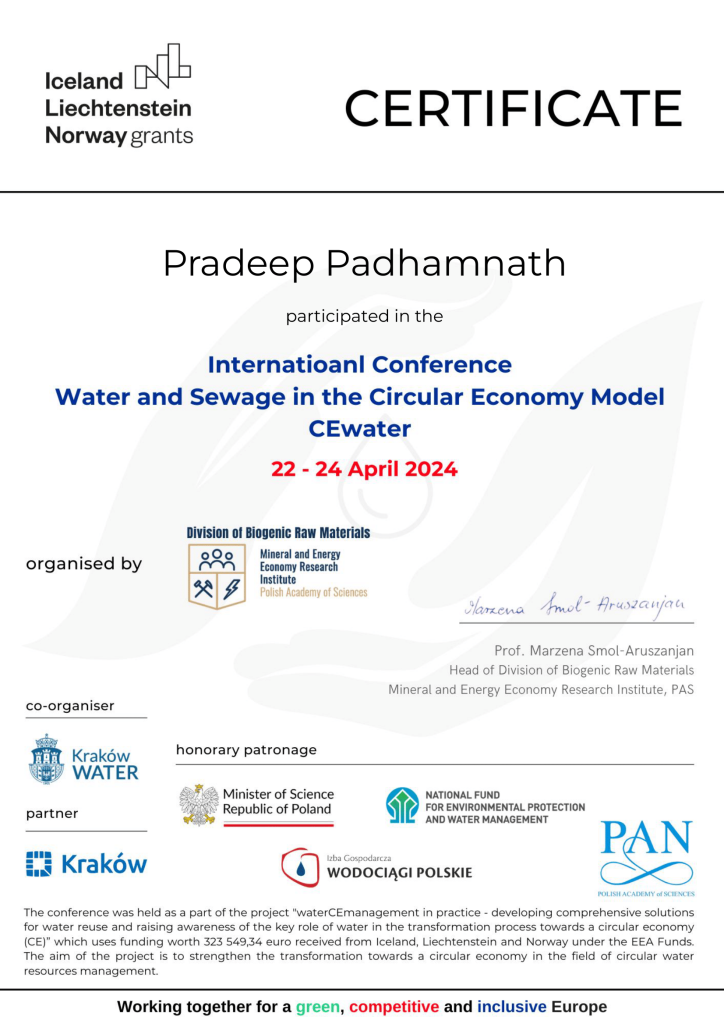

4. International Conference Water and Sewage in the Circular Economy Model (CEwater), Krakow, Poland, 22-24 April, 2024

Dr. Pradeep was invited to attend the International Conference – Water and Sewage in the Circular Economy Model (CEwater) which was a summary of the project entitled „Developing comprehensive water recovery solutions and raising awareness of the key role of water in the transformation process towards a Circular Economy (CE)”. The project used funding from the European Economic Area (EEA) Funds. The aim of the project was to strengthen the transformation towards circular economy in the field of circular water resources management. The aim of the CEwater International Conference 2024 was to summarise the technical achievements in the project, the issues and methods of water and wastewater management, presenting the best practices for implementing Circular Economy in the water and wastewater management sector as part of organisational solutions, technological and educational and informational. The conference included talks from researchers and students working on water recycling and resource management, poster sessions and a visit to the Bielany water treatment plant.

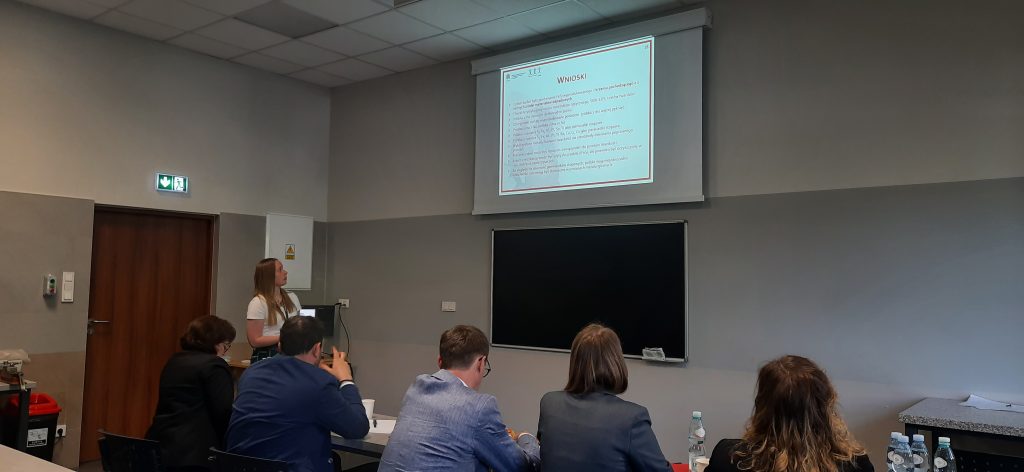

5. Student Conference at the Metallurgist’s Day-2024, AGH, Krakow, 9-10 May, 2024.

Analysis and characterization of ferrosilicon made from recycled silicon and steel scrap. Presented by Julia Mirecka.

On the first day of the two-day long Metallurgist’s day celebration at AGH university, Julia Mirecka who is a third-year undergraduate student and is performing her engineering thesis within the project, presented her research work. She was among the 200 graduate (masters) and undergraduate students selected to give the oral presentation. The topic of her presentation was ’Analysis and characterization of ferrosilicon made from recycled silicon and steel scrap.’ Julia presented detailed analysis of Ferrosilicon done with the help of SEM imaging and Energy Dispersive X-ray spectroscopy. She further analysed the SEM images to find the grain size distribution and identify the different phases. With the help of hardness measurement (Rockwell and Vickers) she presented the analysis of mechanical properties. She stressed on the importance of recycling to align ferrosilicon production with the EU sustainable goals. This was Julia’s first presentation in a conference. Her presentation was applauded, and she received a special commendation from Mesko industries who acknowledge the potential importance of her work for real world applications.

6. European Microscopy Congress, 26-30 August, 2024, Copenhagen, Denmark

The European Microscopy Congress was a confluence of researchers, technicians and scientific equipment manufacturers who converged in Copenhagen for the conference which is held once in every four years. Advanced new methods such as 3D-Electron Diffraction and 4D-STEM for characterization of materials were discussed. Altogether, there were two invited talks, 20 presentations and 45 posters in the physical sciences section. Dr. Pradeep Padhamnath attended the conference as one of the 10 researchers from Poland. The abstract book for the physical science section could be found here.

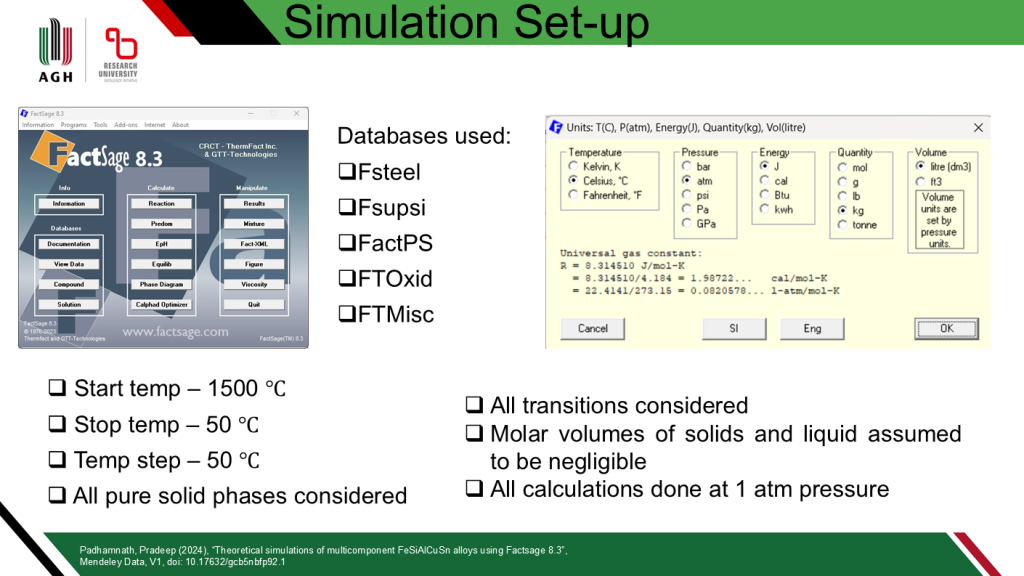

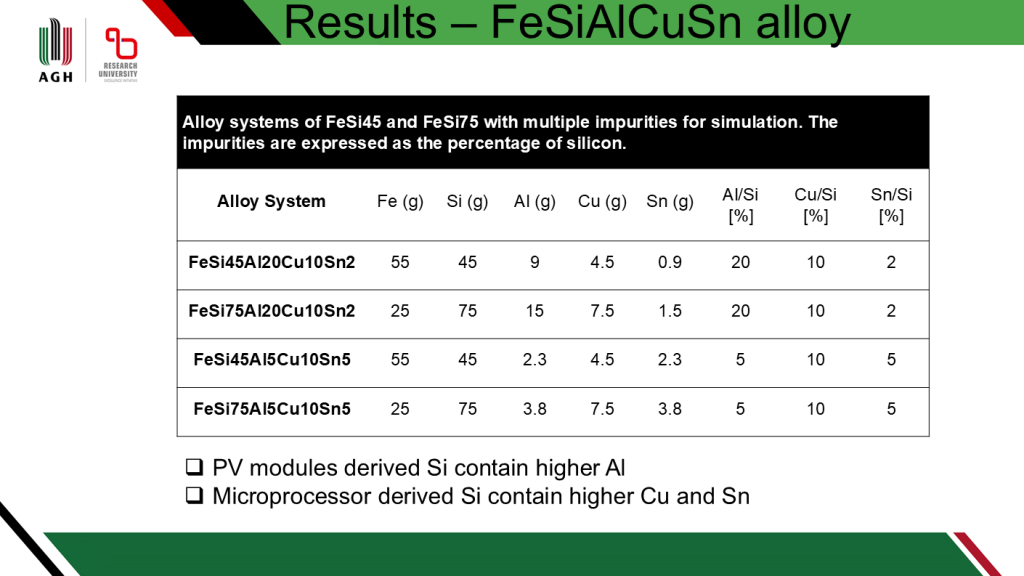

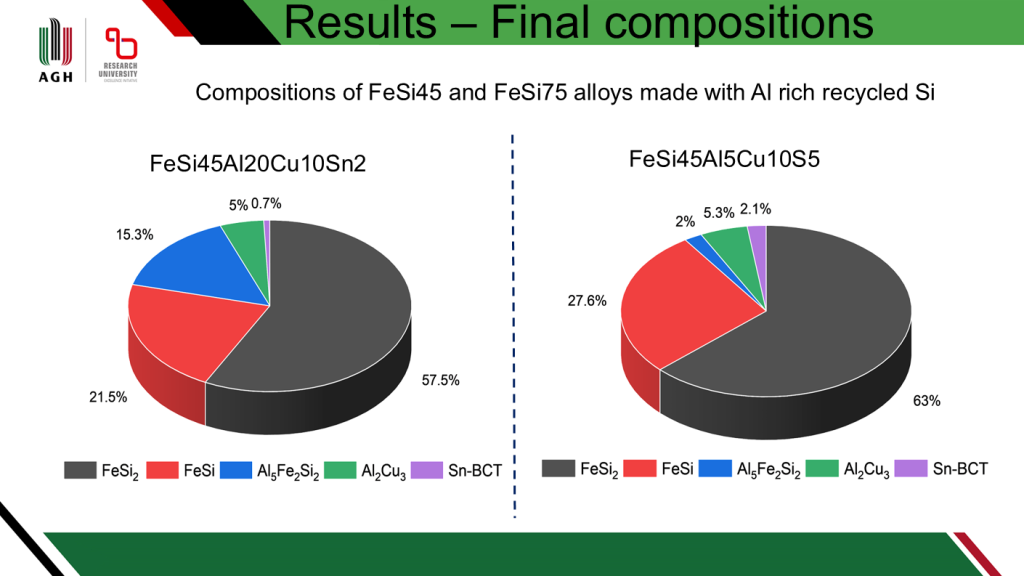

7. Modern Metallurgy, 25-27 September, 2024, Chorzów, Katowice, Poland

Dr. Pradeep Padhamnath presented his work titled „Theoretical investigation of the effect of impurities in recycled silicon used for the production of ferrosilicon” at the XXXI international scientific conference Modern Metallurgy 2024 – Iron and Steel making held at the Museum of Metallurgy in the historic city of Chorzów, near Katowice, Poland. The conference was organized by Silesian University of Technology, Faculty of Materials Engineering, Department of Metallurgy and Recycling. The main objective of this event was to foster the exchange of knowledge, experience and presentation of the latest trends in the field of metallurgy. For many years, this conference has been an international forum for people of science, industry and experts from related fields for a joint discussion on current problems of this industry sector. This applies primarily to issues related to the production of iron and steel, non-ferrous metals, and also such urgent and topical issues as industrial energy and waste treatment and recycling. Decarbonization and sustainable production of iron and steel and other metals were the main topics under discussion in throughout the conference. One of the undoubted advantages of the conference was the harmonious combination of knowledge of the scientific community with practice Industrial. Such integration allows for a holistic view of the development of the metal sector, taking into account issues of technological development, environmental protection, waste generation and management and energy saving. The abstract of Pradeep’s can be found here.

8. Metallization and Interconnection Workshop, 23-24 October, 2024, Bourget-Du-Lac, France.

Dr. Pradeep Padhamnath presented the results of the collaborative work between his team at AGH University of Krakow and researchers from Solar Energy Research Institute of Singapore (SERIS), National University of Singapore on the novel method of recycling end-of-life silicon PV panels using the electrohydraulic fragmentation process. The team at SERIS was responsible for the processing of the solar PV panels using the novel electrohydraulic fragmentation process, while Dr.Pradeep’s team at AGH was responsible for the characterization and evaluating the further use of the materials recovered from the process. The results were presented in a poster session. Dr. Pradeep’s presentation was the only presentation related to recycling and sustainability. Dr. Padhamnath was also a member of the technical committee of the conference and chaired the opening scientific session of the conference related to screen-printed metallization.

Additionally, Dr.Pradeep guided the student members from Eko Energia team from AGH in fabricating and testing light weight and flexible solar-PV modules fabricated at room temperature. The modules were tested for accelerated degradation at SERIS, NUS.

9. 62nd Advanced Materials Congress, International Association of Advanced Materials (IAAM), 29-31 October, 2024, Stockholm, Sweden

Dr. Pradeep was invited to present the prestigious „Advanced Material Scientist Lecture” at the Baltic Series conference at the 62nd Advanced Materials Congress organised by the International Association of Advanced Materials (IAAM). In his 30 min lecture, Dr. Padhamnath presented a status of the current trends in recycling of c-Si PV modules and the state-of-the-art in technologies being developed to handle the large amounts of PV wate. He also presented the work done in his research under the current project, which can be used to handle the discarded PV panels waste in an energy efficient process. Dr. Padhamnath was awarded with a citation for his lecture.

10. Applied Science and Engineering, Nov 7-8,2024 Vienna, Austria

Dr.Pradeep was invited to present the Keynote talk based on his work on recycling of c-Si PV panels in the Applied Science and Engineering conference in Vienna, Austria. Dr. Pradeep’s talk was focused on improving the sustainability of the c-Si PV modules. During the talk he presented highlights of his work on management of waste PV and creating commercially important materials from the PV waste.

11. 5th International conference strategies towards Green Deal Implementation: Water, Raw materials and Energy in Green Transition, Nov, 27-29, 2024, Krakow, Poland

The purpose of the International Conference on Strategies toward Green Deal Implementation – Water, Raw Materials & Energy in Green Transition (ICGreenDeal2024) was to present the issue of climate change and ways to prevent it eg. innovative solutions (technological, environmental, economic, and social) that can be implemented under the Green Deal Strategies. The conference saw high quality talks in the field of Environmental Management, Environmental Protection and Environmental Engineering, which deal with the issues management of water, raw materials and energy. Dr. Pradeep shared the results from his work on recycling of PV modules in the session „Sustainable management of energy resources”. The organiser of the conference was the Division of Biogenic Raw Materials at the Mineral and Energy Economy Research Institute, Polish Academy of Sciences, Cracow (Poland).

12. Sustainable Economy and Ecotechnology Conference, Online, 27-28 Nov, 2024.

In the complex fabric of our contemporary world, the intersection between the global economy and environmental dynamics emerges as a pivotal focal point. Upon reflection on the interplay between these two forces, it is evident that the global economy, a complex entity driven by interconnected industries and evolving trade practices, stands at a critical crossroads. Decisions made today within this economic framework reverberate through generations, shaping the trajectory of nations and influencing the delicate balance of our natural environment. The undeniable prosperity brought about by our economic endeavors has, however, come at a cost – a cost measured in terms of severe environmental consequences. Climate change, pollution, and resource depletion serve as blatant indicators of the toll our current economic practices have taken on the planet. This exploration requires an honest appraisal of the environmental impact of prevalent practices, acknowledging that each facet, from industrial processes to consumer behavior, contributes to a larger narrative of environmental degradation. The imperative to transition toward modern sustainable economic practices lies at the core of this reflection. Recognizing that traditional models of development are often incompatible with long-term ecological well-being is a crucial starting point. The focus is on fostering conversations about reshaping economic paradigms, emphasizing sustainability as a cornerstone for future prosperity. Adopting sustainable economic practices is imperative for the survival of our planet. The aim is to bring together diverse perspectives, ranging from economic theorists to environmental scientists, not for discussions but with the collective intent of designing a roadmap toward a harmonious coexistence of economic growth and environmental preservation. Embedded within these considerations are examples of positive changes and technological advances that offer glimpses of a more sustainable future. The shift towards renewable energy sources, innovative circular economy models, and eco-friendly manufacturing processes serve as inspiration, illustrating that the marriage of economic development and environmental stewardship is not only possible but can be mutually reinforcing. In the conference, Dr Pradeep shared the results from his work on PV module recycling, and how exploring different ways to handling PV waste can lead to unprecedented economic opportunities, in addition to sustainable management of the electronic waste.

13. Computer Methods in Metals Technology (KomPlasTech) 2025, Krynica Zdroj, Poland, 2-5 March, 2025.

The first national conference in the series on Computer Methods in Metals Technology (KomPlasTech) was held in 1993 in Kraków, Poland. The conference was organized by prof. Maciej Pietrzyk (from AGH University of Science and Technology) and prof. Antoni Piela ✟ (from Silesian University of Technology). The first edition was held in Krakow. At the beginning of the 21st century the intention of the organizers was to extend the scope to all materials and to make the conference international by inviting the scientists from all over the world. Thus, several papers dealing with non-metalic materials were submitted and the name of the Conference was changed to Computer Methods in Materials Technology. The first international KomPlasTech Conference was organized in Zakopane in 2007.There is an increasing necessity to solve complex problems in numerical modelling of materials processing. Several new techniques dedicated to description of materials behaviour have been developed. Application of the multiscale analysis to joint modelling of phenomena occurring in different scales (macro, mezo, micro and nano) became effective. Thus, the objective of the KomPlasTech Conference is to get together scientists and researchers working in the fields of computer methods and materials science and industrial partners to enable exchange of information and experiences between those two groups. Adarsh Rai, a Ph.D student working on the project presented a talk titled ” Corrosion Behaviour of Silicon Steel Prepared with Recycled Steel Scrap After 24-Hour Immersion in 3.5 wt% NaCl Solution„.

14. Marie Curie Alumni Association Annual Conference and General Assembly, Krakow, Poland, 19-22 March, 2025.

The Annual Conference and General Assembly is the flagship event of MCAA, supported by EU and MSCA. It brings together hundreds of participants from across the world and different fields of expertise in research, science policy, and industry to discuss topics relevant to the research and innovation sector. Dr Pradeep Padhamnath participated in the event where he was inducted into the Poland Chapter of MCAA and as well as into the Sustainability Working group.

15. Silicon PV, Oxford Univedrsity, United Kindgom, 08-11 April, 2025.

Dr. Pradeep Padhamnath presented the results of his work at the prestigious silicon PV conference held in Oxford, UK from 8-11 April, 2025. Dr. Pradeep’s work on recycling of PV panels was selected as one of the best submissions and he was invited to submit a full-length article in SOLMAT.

16. Applied Science and Engineering, Berlin, Germany, 14-15 April, 2025.

Dr. Pradeep Padhamnath was invited to present a keynote lecture of 45 minutes as the Applied Science and Engineering conference in Berlin to present his work on recycling of EOL PV modules. In this lecture, Dr. Padhamnath shared his insights into the development of silicon PV solar cell and module technologies and provided an update on the current silicon PV module recycling practices.

Collaborative Research

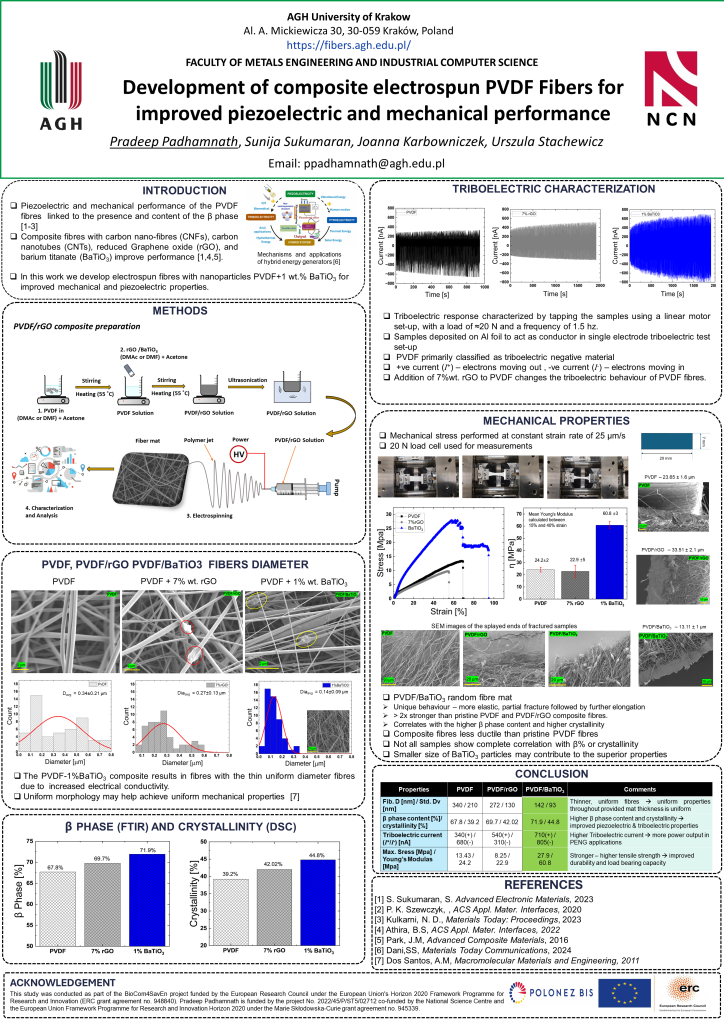

1. 8th International Conference on Electrospinning, 25-28 June, Krakow

PI Pradeep Padhamnath, collaborated with researchers from the Electrospun Fibers Group lead by Prof. Urszula Stachewicz, AGH to develop high performance and durable polymer fibres for energy applications. The team developed advanced composite polyvinylidene difluoride (PVDF) fibres using electrospinning method. Reduced graphene oxide (rGO) and barium titanate (BaTiO3) were used to enhance the properties of the electrospun PVDF fibres. The composite fibres developed using PVDF-BaTiO3 exhibited superior piezoelectric and mechanical properties than pristine PVDF fibres or PVDF-rGo composite fibres. TVDF-BaTiO3 fibres could generate approximately 800nA of current, which was 1.5 times more than the triboelectric current generated by the PVDF-rGO fibres. The PVDF-BaTiO3 composite fibres also withstood 25MPa of mechanical strain which was more than twice that of the PVDF alone or PVDf-rGO. The results of the research work was presented in the 8th International Conference on Electrospinning held at AGH, in Krakow, titled „Development of composite electrospun PVDF fibres for improved piezoelectric performance” (Abstract) Pradeep was awarded the best poster award for his research work on improving the mechanical strength along with the triboelectric performance of the electro spun fibres. The posters were adjudged by Dr David Huesmann, chief editor at Wiley and Dr. Yen Truong, senior research scientist at CSIRO.

University Lectures

1. Renewable fuels through Solar PV, Tuesday, 23 April, 2024

On the invitation of Prof. dr. Hab. Aneta Magdziarz, Dr.Pradeep gave a 150 min lecture on the generation of renewable fuels through solar photovoltaics, with special focus on generation of hydrogen and biofuels. This was an excellent opportunity for Dr.Pradeep to share his decade of experience in working with solar PV and generation of renewable fuels. The lecture was attended by the polish students and international students vising AGH on Erasmus scholarships. Prof. Magdziarz later expressed gratitude for the lecture mentioning „Your lecture was a fantastic opportunity to learn more about hydrogen production using solar energy and renewable fuels in general.”

Public Events

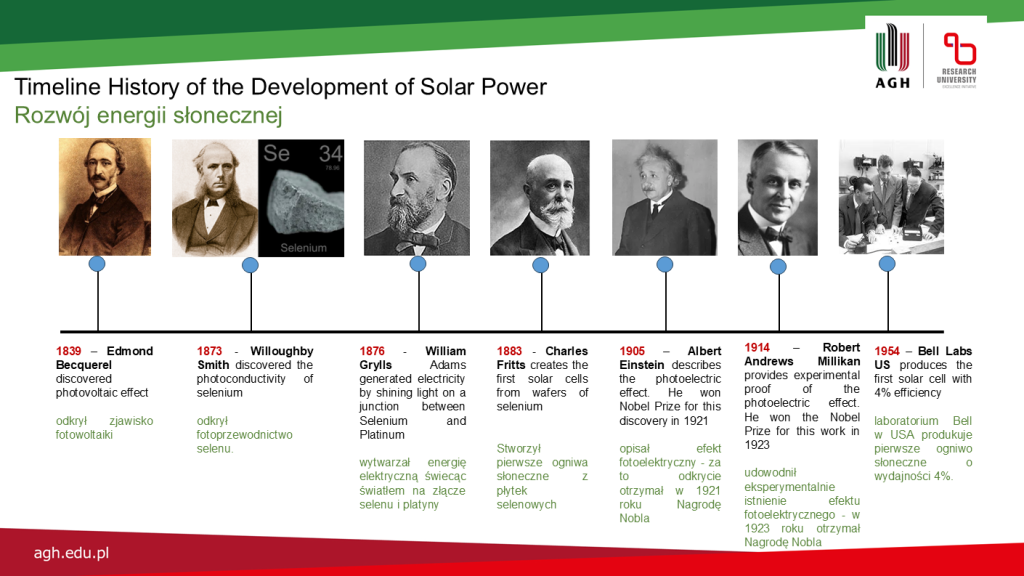

1. Lifecycle of PV Panels – Małopolska noc Naukowców,2023

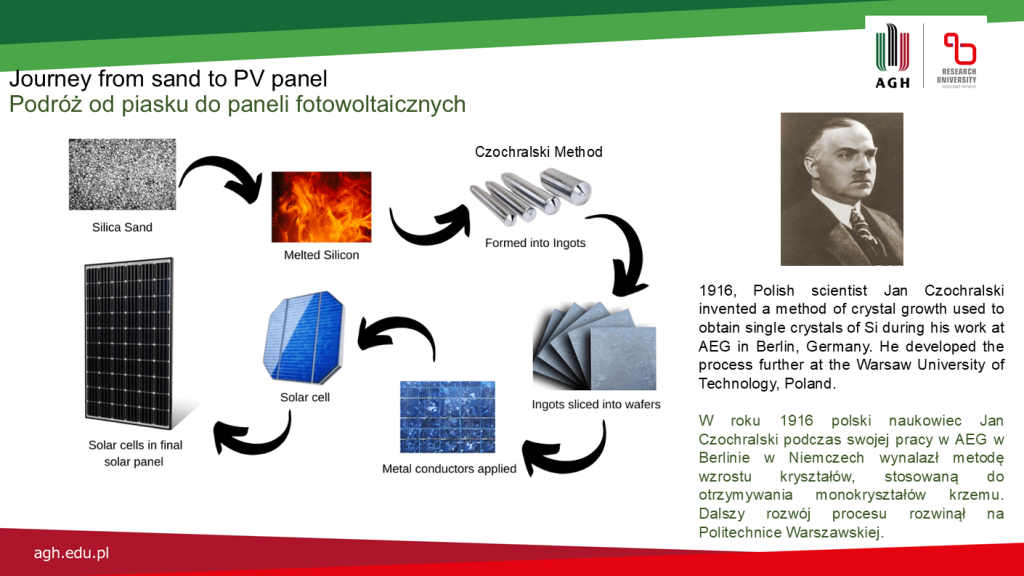

Harnessing solar energy to generate electricity is one of the cleanest and most environmental friendly options. Solar Photovoltaic (PV) panels are easy to install and versatile. They have a warranty of 25 years and can continue to produce energy for more than 50 years. What makes solar panels so efficient ? How does a solar pv panel produce electricity? What happens to a panel after its usable period? In this lecture we shall talk about the components of a solar PV panels, their operating principles and common maintenance practices. We will also present the different options of recycling the waste PV panels. We will show an easy way to calculate the solar PV requirements for your household. This will help in understanding how solar photovoltaics can help in combating climate change and lead to a cleaner, greener, world.

Wykorzystanie energii słonecznej do wytwarzania prądu jest jednym z najczystszych I najbardziej przyjaznych środowisku sposobów produkcji energii elektrycznej. Panele fotowoltaiczne są łatwe w montażu i łatwo adaptowalne (można je instalować w różnych miejscach/konfiguracjach). Posiadają 25-letnie gwarancje i pozwalają na wytwarzanie energii przez ponad 50 lat. Co czyni panele solarne tak efektywnymi? Jak panele fotowoltaiczne produkują energię? Co dzieje się z panelami po upływie ich przydatności? Na tym wykładzie opowiemy o elementach, które tworzą panele fotowoltaiczne, o zasadzie ich działania oraz o sposobach ich konserwacji. Pokarzemy również różne sposoby przetwarzania odpadów pochodzących z paneli fotowoltaicznych. Zaprezentujemy prosty sposób na obliczenie ilości paneli potrzebnych w waszych domach. To wszystko pomoże zrozumieć, jak fotowoltaika słoneczna może nas wspomóc podczas zmian klimatycznych w walce o czysty, zielony świat.

Day & date – Friday, 29, September, 2023

Time – 18.00-18.45; 19.00–19.45

Location – BUILDING B4, ROOM 122, AGH UST, MICKIEWICZA 30; 30-059 KRAKOW

For more details, please click here.

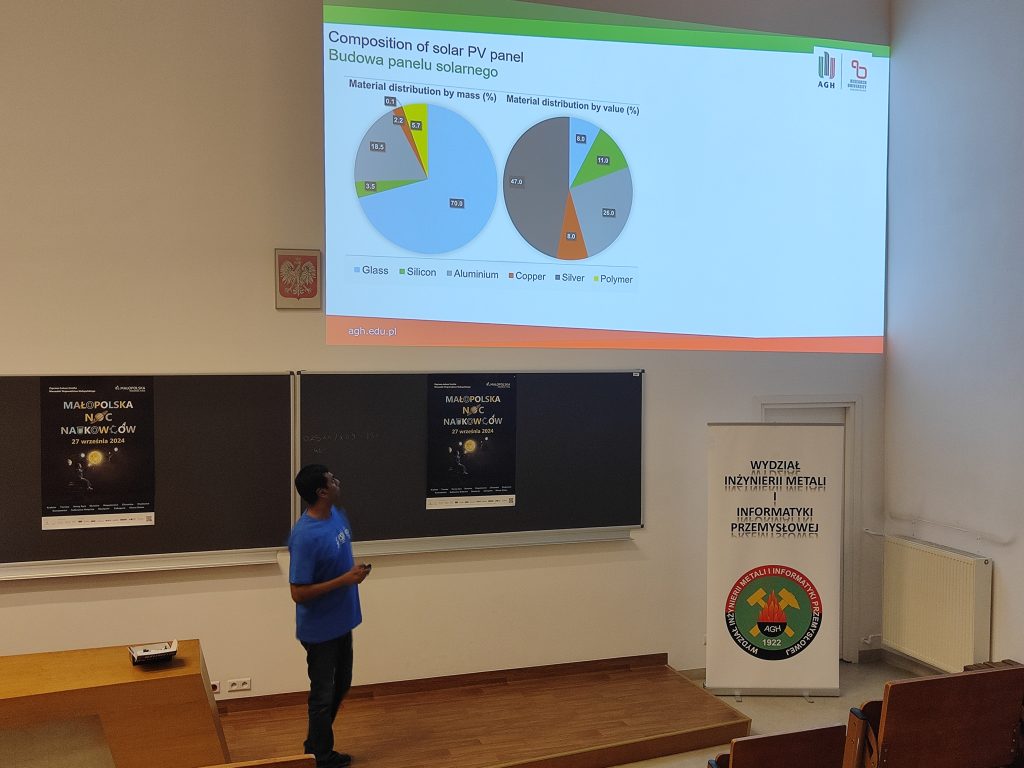

2. Solar PV – The hero of clean energy production and 100% recyclable- Małopolska noc Naukowców,2024

Harnessing solar energy to generate electricity is one of the cleanest and most environmentally friendly options. Solar Photovoltaic (PV) panels are easy to install and versatile. They have a warranty of 25 years and can continue to produce energy for more

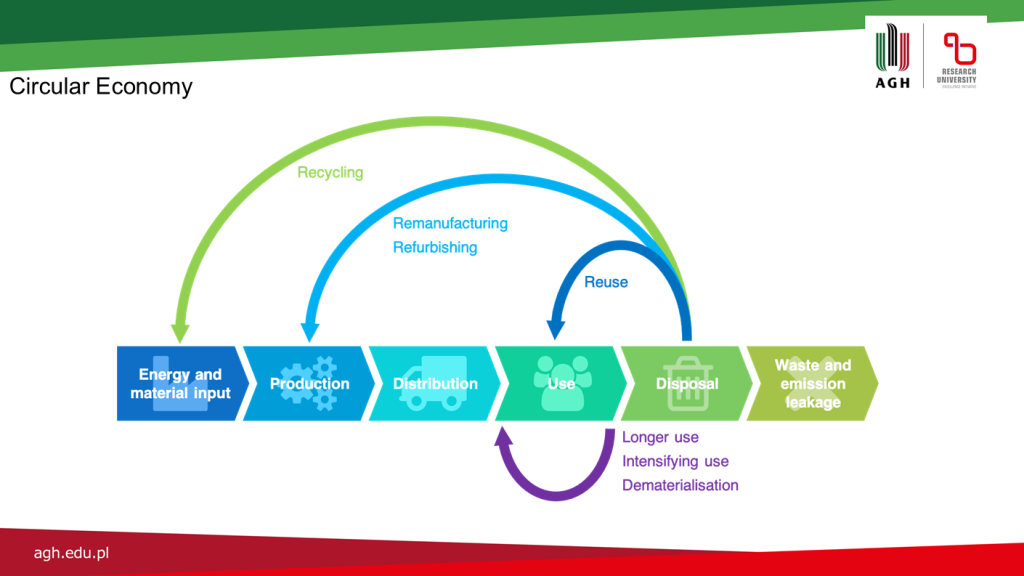

than 50 years. What makes solar panels so efficient? How does a solar pv panel produce electricity? What happens to a panel after its usable period? In this lecture we shall talk about the components of a solar PV panels and their operating principles. We will also discuss different applications and options of recycling the waste PV panels and extracting valuable materials from it, leading to circular economy. This will help us understand why PV are the among the best options for creating a cleaner greener world.

Using solar energy to generate electricity is one of the cleanest and most environmentally friendly options. Photovoltaic (PV) panels are easy to install and versatile. They come with a 25-year warranty and can continue to produce energy for more than 50 years. What makes solar panels so efficient? How does a solar panel generate electricity? What happens to the panel after it has been used? In this lecture, we will discuss the components of solar panels and how they work. We will also discuss the different applications and possibilities of recycling used solar panels and extracting valuable materials from them, leading to a circular economy. This will help us understand why solar is one of the best options for creating a cleaner, greener world.

Day & date – Friday, 27, September, 2024

Time – 19.00–20:00

Location – BUILDING B4, ROOM 122, AGH UST, MICKIEWICZA 30; 30-059 KRAKOW

For more details, please click here.

Image gallery

- June, 2023: Pics from the POLONEZ BIS kick off meeting held in Kraków, Poland.

Past Events

Student scholarship

We are hiring students. We have two open positions. Please refer to the call on NCN websites on the following links:

https://www2.ncn.gov.pl/baza-ofert/?akcja=wyswietl&id=222957

https://www2.ncn.gov.pl/baza-ofert/?akcja=wyswietl&id=222958

Application deadline – Nov 20, 2023